- News

- Subscribe

Get full access to The Motorship content

Including the digital magazine, full news archive, podcasts, webinars and articles on innovations and current trends in the shipping industry.

- Expert analysis and comment

- Unlimited access to in-depth articles and premium content

- Full access to all our online archive

Alternatively REGISTER for website access and sign up for email alerts

- White Papers

- Industry Database

- Events

Propulsion & Future Fuels Conference 2025

The Motorship’s Propulsion & Future Fuels is the leading international conference on powering shipping’s emissions-cutting ambitions.

The 2025 Conference will take place from 25th - 27th November in Hamburg, Germany and will offer a meeting place to learn, discuss and knowledge-share the latest developments in efficient power and propulsion technology plus alternative low flashpoint and low carbon fuels.

Click here for more information

Slow steaming: A strategy with unintended consequences

As more shipowners adopt slow steaming to reduce fuel consumption and emissions, maritime consultancy Houlder warns that without data-driven analysis, the practice may lead to unintended financial impacts and potentially hinder progress towards the IMO’s greenhouse gas reduction targets.

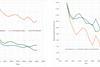

Slow steaming, the practice of operating vessels at reduced speeds, can influence vessel efficiency in various ways, depending on a ship’s original design, hydrodynamic performance, and operational profile. Houlder’s analysis of Clarksons’ data reveals a marked decline in average service speeds across multiple vessel types—oil tankers, bulkers, and container ships—from 2012 to 2024. Container ships experienced the greatest slowdown, with an average speed reduction of 1.50 knots (-11%) by 2024, followed by bulk carriers (-9%) and oil tankers (-6%).

While slow steaming can reduce power consumption and GHG emissions, it may also deviate significantly from a ship’s design parameters, impacting both performance and maintenance costs. Iebum Shin, data analytics lead at Houlder, cautions that “simple retrofits such as hull modifications or propeller optimisation could determine whether slow steaming delivers marginal or substantial benefits.”

Continue this article…

Already subscribed? SIGN IN now

Register for a FREE one-month trial to continue this article

Want to read more before deciding on a subscription? It only takes a minute to sign up for a free account and you’ll get to enjoy:

- Weekly newsletters providing valuable news and information on the shipping sector

- Full access to our news archive

- Live and archived webinars, podcasts and videos

- Articles on innovations and current trends in the shipping industry

- Our extensive archive of data, research and intelligence

Get more free content sign up today

Ready to subscribe? Choose from one of our subscription packages for unlimited access!