Full transcript of the podcast

The Motorship: Hi, welcome to another edition of the Motorship podcast. Today I have Peter Hansten, who is the director of Business Development for Project services at Wärtsilä . Hello, Peter.

Peter Hanstén: No, David, thank you for the opportunity to be here.

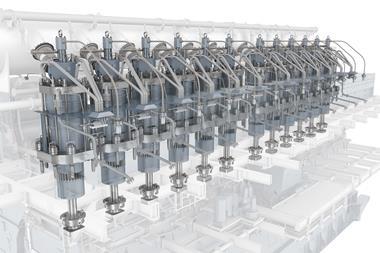

TMS: Thank you very much. Peter, I understand you’ve been at Wärtsilä since the the mid 90s and you were involved with the Vassar engine. They actually Vassar 32, low nitrogen oxide engine. You’re a design engineer, I think that’s true. And I think you’re married with a son and two dogs and since the 90s, you’ve seen things really evolve. You’ve seen the focus on nitrogen oxides and sulphur oxides. I think leads to acid rain and now We’ll spin to modern days when FuelEU Maritime is really focusing on the marine sector and trying to decarbonise it, I’ve read your reports on decarboniaation strategies, Peter and I see the company seems to highlight there’s no single technology or a silver bullet, panacea for decarbonization. How do you go about determining the best combination of technologies for a single vessel or for an entire fleets Peter if you can let me know about that?

PH: Yes, I guess one of the most important things to note is that the path towards decarbonization is fairly complex. With factors like ambitious targets, you have the indexes with compliances local and international regulations of course. Then also infrastructure needs job.

Considerations and as well, of course, also the technology, technological maturity of different solutions. And that’s why it’s important too.

Let’s create a unique decarbonisation strategy for the ship owners and and that advertising we offer decarbonization modelling services.

Which then support owners and operators with established an optimal decarbonisation path for their ships.

TMS: Cause you say you use a digital twin, don’t you? It’s in some in some aspects. Please can you tell me a bit more about that please?

PH: So yeah, so we do this by creating a digital model of the ship, which is developed by combining operational data from several different sources.

And using utilising the modelling capabilities and machine learning algorithm developed by by people in in the team to deliver a detailed analysis of the of the business operational data.

And in that each case is of course unique and the modelling could then consider many different issues like routes, the way you’re operating, availability of fuels, space on board, investments versus residual value of the vessels and and many more. Then this model is used to simulate the impact of the different technologies. Several different technologies, thus identifying the most beneficial and prudent solution or combination of solutions for the ship owner.

TMS: Can you show me more about how the hybridization modelling for the Regal Princess led to discovering additional beneficial technologies and maybe what lessons can other companies learn from that process Peter please.

PH: Yes. So in back in 2021, Carnival Corporation approached Wärtsilä to help it planned the optimal league conversation par 5 for one of the cruise versus the Regal Princess. When we started working with Carnival on this project, they had the it’s a clear idea of its decommission technology, have interest in and they wanted.

Help with evaluating the potential impacts of these technologies and also pioritising the order in which to implement them In then through our 3D conversation modelling services as mentioned earlier, we tested the feasibility by the impact of these decarbonization approaches and this was done through then getting a lot of different operational data from the Regal Princess vessel.

TMS: OK. And with the company, I understand you have to be sort of technology agnostic in some respect. How you do that and also what sets do we all sort of decarbonisation? Consultancy apart from maybe other service providers? It seems to be quite a quite a hot market at the moment with the regulations and things like coming in. Peter.

PH: That’s maybe maybe make one thing clear first that we we have recognised that there is not one-size-fits-all solution for decarbonisation. So that’s why our decarbonisation approach is is designed to tailor the flexible solutions then to the unique needs of each owner and operator ensuring that they are equipped with the correct technologies at the at the right time. The same applies on how to work with the customers. As a company, we don’t just sell the product or technology we provide partnership and we want to partner with our customers to help the transition in at at the right pace at the right time and with the right tools for their business. So we actually is do we don’t start from the product or technology we we start by understanding the challenges they face and what the business needs are.

And there are several factors which make this possible. First of all, we virtually we have one of the broadest technology portfolios in the market.

This means that we can offer many different options for the customers.

What more our offering then includes real time insight into operations performance and reduce performance based agreements, even upgrades, life cycle solutions and of course then supported by the global network of maritime experts on the service side.

TMS: These partnerships, and I wonder, is it important that they’re sort of cross industry collaboration to advance decarbonisation more generally, Peter?

PH: Yes, indeed. Not one part of or company holds all the knowledge or competence or experience to do this alone.

That of course, even includes ourselves at virtually the global nature of shipping means that working together with others is the only way that the industry can unlock the potential to drive this sustainable transformation and develop technologies and solutions that meet the needs of a wider value chain. So that’s why we actively engage in partnerships and initiative initiatives aming at the advanced sustainable practises.

TMS: That evolved quite a bit in the last 30 years. Peter, I’m just wondering, can you give me an example of that perhaps of how this has evolved over 30 years?

PH: I would say it’s you can see that it’s of course not only marine or shipping that’s changed, but all of this one is that I would say gone very much from a transactional being a supplier buyer Into more understanding the whole bigger picture and and not only value chain but the value network and taking for example this good now with with the whole decarbonization. The availability technique different technologies, how at at what time, at when at what price. So there is clearly that kind of this buyer and and seller relationship. It is not sufficient to drive this transformation in shipping.

TMS: No, I mean, I’ve asked you to sort of look back in time there. Now I’m going to ask you to get your crystal ball out and look forward. How do you see developments coming in the marine industry, say over the the next decade when I suppose decarbonisation pressures are only going to increase? Peter, aren’t they?

PH: Yeah. So and of course this will all evolve over time and basically you could say that three main pathways.

For the decarbonization of marine industry, 1st and most current is maybe to burn less fuels and that’s around in vessel and operation efficiency is of course is about to reduce the GSD emissions and fuel cost. And this typically now what we see of course in the industry energy efficiency improvements.

Of the engines and your saving technologies, all another system and speed reduction route optimization.

And of course, onboard energy management and hybrid system. So this is really kind of what’s said, a quick fix and on the short horizon.

Then next step to take it deeper or.even reduce more is to clean up the emissions. That’s the second pathway.

And using emission abatements, then for it, we get impact and more significant impact reduction of the GST emissions or of the carbon based fuels with onboard carbon capture for example.

The final the the the third main pathway is sustainable fuels and electrification and then of course we’re talking about treduction of the GHG emissions through sustainable fuels.

There, of course, is a mixed of methanol, ammonia, for example.

Even maybe some application in future hydrogen.

And then, of course, electrification, also like in many other industries, we we see that like a car industry with its may be most familiar many of us and aviation also so electrification.

TMS: Well, I’ve asked you before about being technology agnostic. It sounds there if you’re sort of looking to the future, that parts there are kind of maybe fuel agnostic as well. I mean, do you see do you foresee a multi fuel feature in the future?

PH: Yes. And it’s clearly to have this flexibility is essential here because we all know that the lifespan of a vessel is is within 2530 years etcetera and reaching the targets then of of net zero by close to 2050. It’s it’s clear that whoever now we invest in whether a new vessel or or make a retrofit need to consider the flexibility of use and over the lifespan of the vessel.